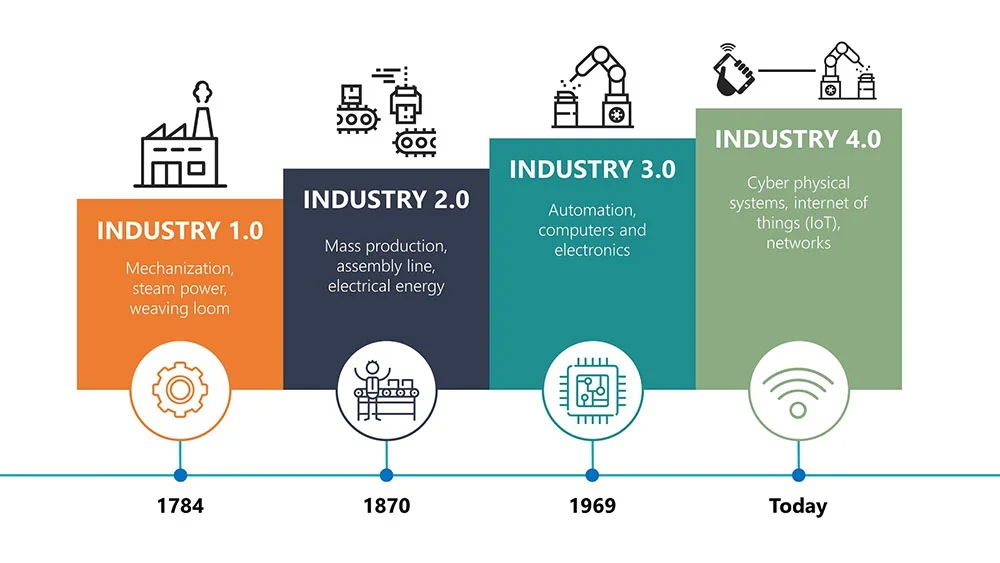

The first industrial revolution began with the mechanization and mechanical power generation in 1800s. It brought the transition from manual work to the first manufacturing processes; mostly in textile industry. An improved quality of life was a main driver of the change.

The second industrial revolution was triggered by electrification that enabled industrialization and mass production. Often mentioned in this context is a quote of Henry Ford, who said about the Ford T-Model car ‘You can have any colour as long as it is black.’. The quote captures well the introduction of mass production but without the possibility of products’ customization.

The third industrial revolution is characterized by the digitalization with introduction of microelectronics and automation. In manufacturing this facilitates flexible production, where a variety of products is manufactured on flexible production lines with programmable machines. Such production systems however still do not have flexibility concerning production quantity.

Today we are in the fourth industrial revolution that was triggered by the development of Information and Communications Technologies (ICT). Its technological basis is smart automation of cyber-physical systems with decentralized control and advanced connectivity (IoT functionalities). The consequence of this new technology for industrial production systems is reorganization of classical hierarchical automation systems to self-organizing cyber physical production system that allows flexible mass custom production and flexibility in production quantity.

https://iot-analytics.com/industry-4-0-and-smart-manufacturing/

https://iot-analytics.com/industry-4-0-and-smart-manufacturing/

×

×